One of the most outstanding innovations by Lagarde Autoclaves was the development of the retort with Steam & Air process in 1972

(Patent Nr. FR2225702).

We are THE INVENTOR

We are THE FIRST

We are THE ORIGINAL

This innovation was born from the industry demand: productivity improvements and thermal treatment safety as well as new packaging exploration and lower production costs.

This invention had a significant impact on the world of thermal processes.

The Steam and Air process embodies energy savings and environmental commitment for Lagarde autoclaves.

Each new Lagarde Steam and Air retort is designed with the following features to reduce production costs and environmental footprint:

Temperature Come-up and Holding Time:

Steam is automatically and directly injected into the retort chamber and properly distributed; a fan agitating the steam and air with efficiency enable a uniform heat distribution in the entire retort chamber in order to guarantee good temperature accuracy during the holding time.

Cooling Step:

Cooling is achieved with recirculated cooled water by fresh water or via a Plate Heat Exchanger.

Water comes from steam condensate.

During all the Heat and Cooling steps, the system is monitoring the temperature and the pressure inside the retort chamber.

Lagarde Autoclaves machines are stand out with the last technologies, highest manufacture quality and stunning value for money. We will help you to find the most appropriate retort in accordance with your needs and expectations.

We offer a large range of product, and we are able to conceive a tailor-made retort fully suitable for you, from the smallest to the biggest project:

Static or rotary

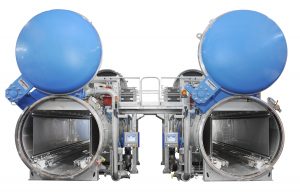

From Ø900 mm to Ø2000 mm

From 1 to 12 baskets

1 or 2 doors

Manual and automatic, hinged or vertical sliding doors

In 2009 Lagarde Autoclaves designed and manufactured the first Ø2000 tunnel retort. Perfectly suitable for the high productivity, it optimize the available work space. This retort is equipped with the unique Lagarde Steam & Air process, and it perfectly matches with industrial challenges: